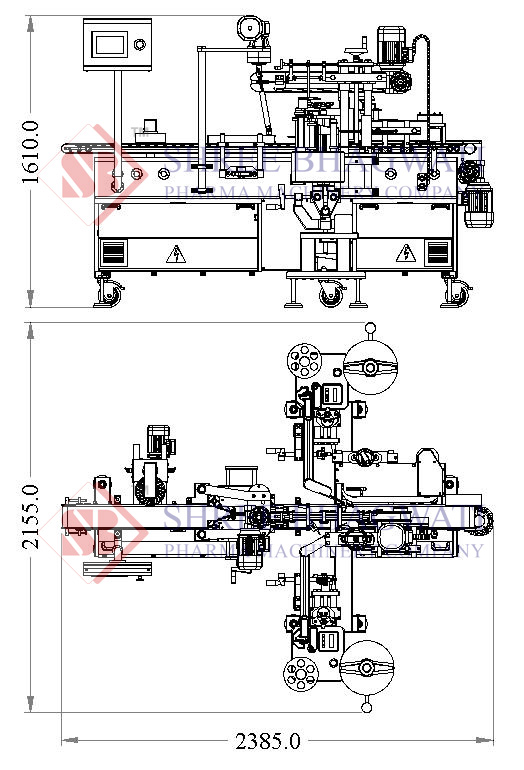

The front and back bottle sticker labeling machine is a fully automatic, sturdy and linear model. The front and back labeling machine is the ideal equipment for applying labels on both the front and back side of flat, round, oval, square, rectangular shaped bottles of various sizes. This multi pack model is highly user friendly and long lasting. It is capable of delivering an output of maximum 120 labels in a minute depending on the size of product and label. It even includes the latest product alignment system that is synchronized with the top holding belt system. This vertical equipment also has a processor controlled label dispensing system; and a sensing system for labels and products. The front and back labeling machine also incorporates a unique single point synchronized speed control system. Further, the sophisticated label length detecting system helps to prevent manual feeding and storing of label length data into the memory, and retrieving the same details every time to change the label size, and restart the equipment. This preset system thus saves time, overall cost, decreases machine down time, and increases productivity.

Disinfectant Bottle Labelling Machine For Front & Back Labeling

The disinfectant bottle labelling machine is also available with an optional safety cabinet made from toughened glass or acrylic. Actually this model 120F of the front and back labeling machine has all the primary features of the standard equipment. Hence it matches the requirements of the different users of packaging equipments in the national as well as international market. Besides this, the disinfectant bottle labelling machine has simple to use adjustments, and needs least changing of tools or components. The front & back labelling machine can also be specially designed with a feed worm system and pocket system, for ensuring accurate alignment of the bottles on the conveyor to label the bottles perfectly. It includes a single point online speed variation control system; and is also suitable for partial or full wrap around and overlap labeling.