Introduction – Labelling has become a very important part of consumerism and marketing of products and brands because any product that is demanded has to be labelled to attract consumers while making it attractive enough to be picked up and also providing all the necessary and crisp details about the product. Appropriate labelling makes it easier for a massive turnover, accuracy, and less handling of unwanted substances. An overview of a few types of labeling machines and their usage can be helpful to give a clear conceptualization.

Rotary labeling machine for the bottle

The Rotary bottle labeller is most suitable for single, double, or multi-side labeling of the round, square and irregular type bottle. It uses a mechanical rotary positioning and uses the concept of the anchor point which enables it to have a great stick mark ability and high positioning accuracy. It can enable labeling at various speeds and a changeover of the bottle does not require changing the parts of the labelling machinery. The Servo drive results in utmost accuracy and minimal damage of labels. It is a fully automatic machine and its applications suit the seasoning, cosmetics, beer, wine, other liquors, and medicine industry.

Pharma Carton labeling machine

This tamper-free labeller is designed to suit the specific needs of labeling and coding of the pharmaceutical industry. They are high-performance machines that ensure automatic labeling on each side of the carton and ensure they are sealed with a unique identity. They cater to a wide range of carton sizes with high speed and provide complete traceability. The double and multi-sided carton labelers have programmable drives with operational simplicity and are very cost-efficient.

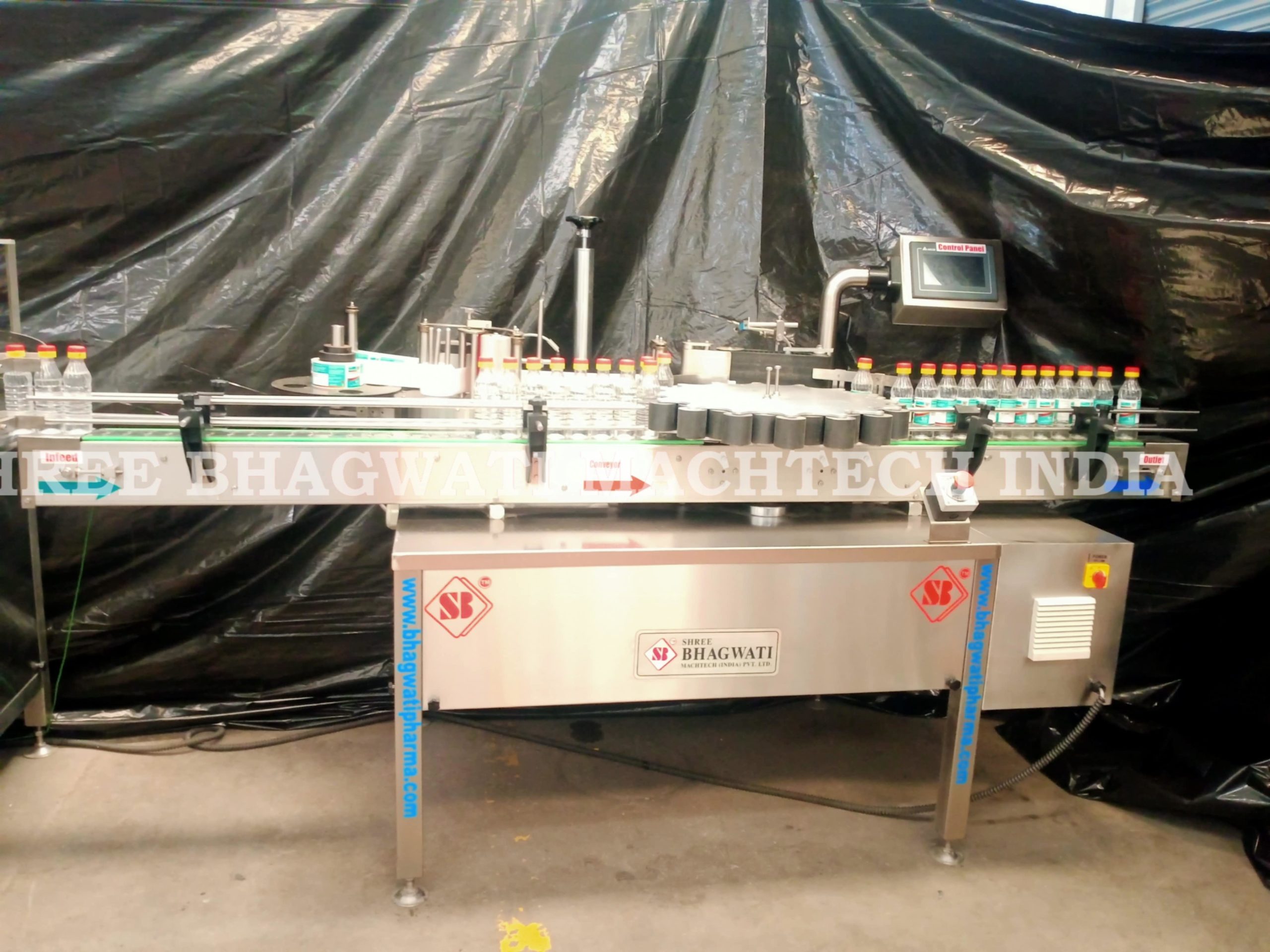

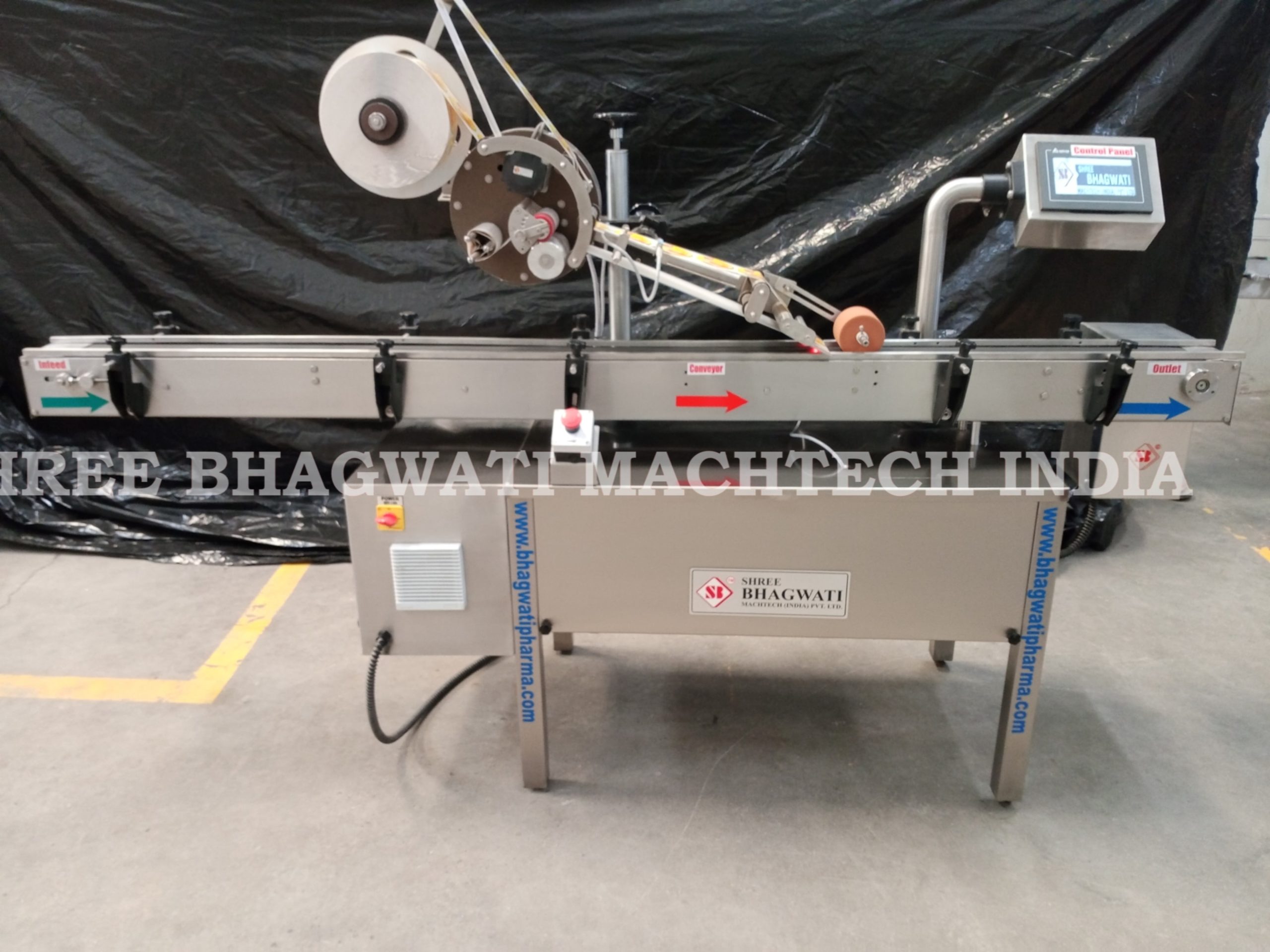

TOP Side labeling machine

The Top label applicator or the top side sticker labeling machines are easily portable and can apply labels on different ranges of products. They are useful in packaging objects and carton tops that need top surface labeling. They can be available in a linear model which can make labeling very quick and streamlined. This smooth operation benefits industries like chemicals, pesticides, agriculture, pharmaceuticals, cosmetics, and many more. These labelers are versatile enough to be used on flat, square rectangular, and round bottles.

Carton top and side labeling machine

When it comes to the wholesale trade, the bottles and containers are packed in a box or carton and transported to the destination for sale to the end-user. The Carton Top and side labeling machine is a PLC-based machine that can give high performance out in line with the operator’s container feeding ability. The side labeling gets as important as the top labeling as this type of data is used to apply variable data such as batch number, list of ingredients and is highly used in food packaging, cosmetic, and household products.

Water for injection labeling machine – WFI labeling machine, IV bottle labeling machine

The Water for injection labeller is most importantly used for pharmaceutical products including the use in injectable drugs. This is a highly efficient technique that places the label in the injection mould and bonding the label with the products. They provide total perfection and eliminate any wastage and tampering. The IV Bottle Labelling machine can rule out any pin holes that may be formed by filling in a blow seal or using the FFS bottle pack machine. During operations, sometimes a minute pinhole cannot be detected but when it passes through this machine under pressure the pinholes open immediately and are given the leak and spraying and the machine ensures there is no leakage.

FMCG Cosmetic product labeling machine for shampoo, Lotion, Hair oil, cream

There are specialized versions and high-speed labelling equipment and production units that allow for complete automation. They have the print and label, label sensor detector, rejection system, and camera vision embedded in them. The fully synchronized versions make it convenient for labeling and all cosmetic needs are well met so that they appear attractive and are picked off the shelf. The versatile labelers suit the front, back, and multi-panel applications including the containers with spin wrap (Spin in place styles).

Bottom Line- The different types of labeling machines and their usage with industry and product specifications have been made very easy with advanced research and technology and easy worldwide installation. They make it a simple world by providing ease, quick turnover, informativeness, and a well-protected product in the most cost-effective manner.