A Front & Back Labelling Machine incorporates sophisticated features to minimize the amount of manual input. Its single-point synchronized speed control system avoids label feeding or retrieval each time it is used, which reduces downtime and increases productivity. It also incorporates a sophisticated label length detecting system to eliminate manual data feeding. Its compact design and high-speed capabilities enable it to meet the needs of even the largest businesses.

Automatic Bottle Labeling

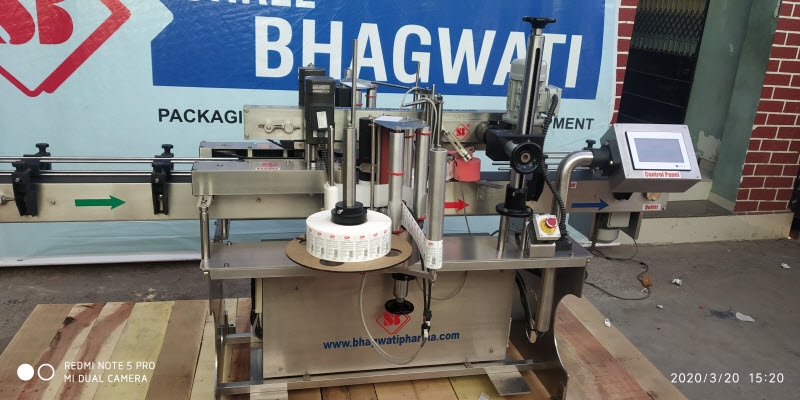

The automatic bottle labelling machine has the following features: It is easy to operate, requires fewer tools, and requires no maintenance. It can perform the following tasks: it separates the product from the bottle, applies a label to the product, rolls the bottle over the label, and completes the labeling action. The automatic bottle labelling machine can be connected with the assembly packaging line for automatic realization of other processes, including product inspection and delivery.

The fully automatic labeling machine is mounted on casters for easy installation and movement. It has a stepping servo motor for labeling and a PLC control system for determining the right positioning for each label. The bottle labelling machine can also be operated independently, or in conjunction with other machines. For high-volume labeling, it is best to opt for an automatic bottle labelling machine that can print barcodes and lot numbers on labels.

Automatic Wrap-around Labeling

For businesses that use a variety of containers, automatic wrap-around labeling is an excellent solution. This technique allows them to print individual labels for prescription bottles, reducing costs and maximizing print space. Additionally, this process allows them to include all of their brand information on one label, while also simplifying UPC specification. The process is easy, resulting in a reduction of time and money spent on manual labeling.

The Basic Machine Range offers a wide variety of features and benefits, including the ability to apply self-adhesive labels on a variety of different shapes. These machines are commonly used in the pharmaceutical, chemical, and food processing industries. Automatic wrap-around labelling machines also come in a variety of designs, including top-applied labels, horizontal wraparound labeling, and front & back labels.

Automatic Top & Bottom Labeling

An Automatic Top & Bottom Labeling Machine is a highly versatile machine that applies labels to the various sides of a pouch or carton. These machines are ideal for surface labeling activity, as the system synchronizes its components to maintain precise labeling even during halting. Bottles are fed into the machine using a feed framework. When the bottles fall down the conveyor, a sensor detects their position and sticks the label at the correct place.

The Automatic Top and Bottom Labeling System is available in different configurations, such as conveyors or transport belts. These machines can be semi-automatic or fully automatic. Semi-automatic top and bottom labelers typically utilize a platform or base, with the labeling head mounted over the top. The latter is more suitable for pliable containers such as glass bottles and clamshells. With its versatile design, automatic top & bottom labeling machines make their use in a variety of industries.

Automatic Side Labeling

Automatic side labeling with front & back bottle labelling machines are designed for a wide range of packaging applications. They can apply labels on both sides of the bottle and can be used on square, round, flat, or oblong bottles. These machines are controlled by servo motors, ensuring precise placement of labels on the two sides of the bottle.

The main use of automatic side labeling with front & back labeling machines is in industries manufacturing pharmaceuticals, dry syrup, honey, edible oils, lubricants, hair oil, cosmetics, wine, and more. These machines can also be used for labelling printed Shrink sleeve and Duplex cartons. The cost of labor is significantly higher with multiple employees, including holiday pay, excursion days, and breaks.