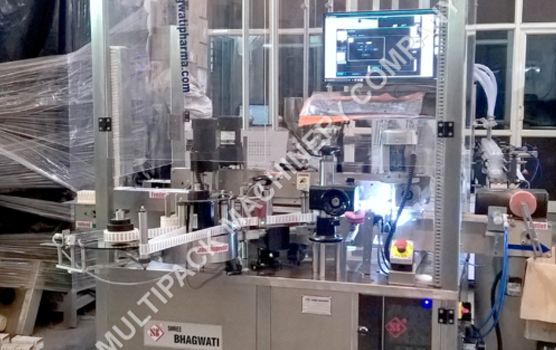

Automatic Carton Corner Labeling Machine One or Two Side Carton Labeler Machine

Not only Single, We Take Care of Both Side of Your Labeling Needs

SPECIFICATION OF THE EQUIPMENT MACHINE’S BASICS

| PARTICULAR | SPECIFICATION |

| Machine Name | Automatic Carton Corner Labeling Machine One or Two Side Carton Labeler Machine |

| Model | Servo Model |

| Production Speed Per Minute | Up to 80 Containers per Minute (Speed Depends up on the length of label and diameter of product and Operator Skills). |

| Suitable for Products | Carton / Box |

| Loading and unloading | Manually (one by one) / Online provision available |

| Application | Single / Double Side |

| Sensors | For Product and Paper Label

(Transparent label – Extra Cost) |

| Label Accuracy Controlling System | Servo Motor |

| Operating System | HMI + PLC controlling |

| Labels Requirement | Self Adhesive Sticker Labels in Roll Form having consistence 3 mm gaps between the 2 labels. |

| Label Material | Self Adhesive Paper Labels |

| Label Roll Outer Diameter | Maximum 300 mm |

| Label Roll Direction | Left to Right |

| Label Core ID | 75 mm |

| Label Dispensing Accuracy | +1 mm |

| Working Height | 860 mm (+/-50 mm) |

| Conveyor Length | 8 Feet |

| Conveyor Movement Direction | Left to Right |

| Machine Weight | Approx 300 Kgs |

| Machine Dimension | Approx 8 (L) x 5 (W) x 4 (H) – in Feet |

MACHINE’S MATERIAL OF CONSTRUCTION

| PARTICULAR | SPECIFICATION |

| Machine Main Base Frame | Stainless Steel 304 Pipe Structure |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Conveyor Slat | Rubber belt (Stainless Steel – for heavy box) |

| Conveyor Shafts | Mild Steel with Hard Chrome or Zinc Plating |

| Conveyor Sprockets | Mild Steel or Nylon |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | Zinc / Hard Chrome / Blackening |

| Feeder Belt (If required for customer’s product) | Timing Sponge Belt |

| Guide Rod & Pin | Stainless Steel 304 |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |