Automatic induction cap sealing machine is designed for rapid and reliable performance. When performance and system control are crucial to your operation, then this is the equipment for you. It has a touch screen input and controller for high tech sealing operation especially suitable in pharmaceutical applications.

The induction cap sealer meets all the required industry requirements and therefore recommended for other industries such as food, beverage, cosmetics, oil packaging and chemical manufacturing industries.

This equipment can be used for both low production as well as high production runs making it among the best equipments for industries with a wide range of products for packaging.

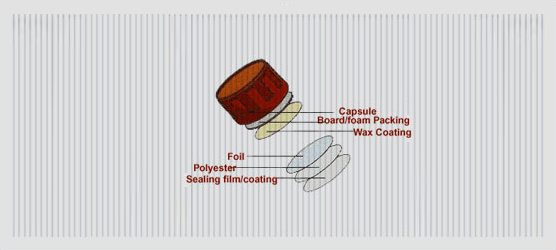

The equipment produces the best hermetic oxygen barrier that ultimately extends the shelf life of the product with no possibility of leakages or seal damage.