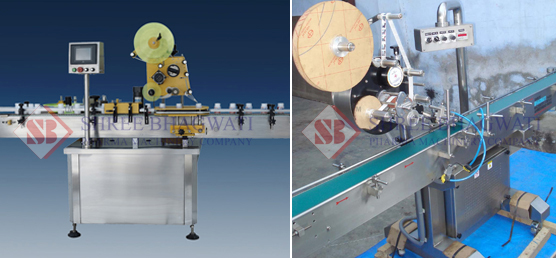

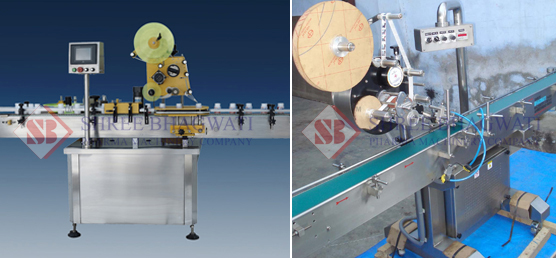

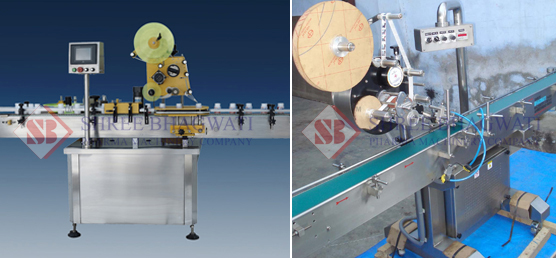

This sophisticated model of the horizontal top sticker labeling machine is very sturdy and extremely user friendly. It has a smooth stainless steel finish on body and main frame. The top side labeling machine includes the latest micro processor controlled system of label dispensing, as well as a modern sensing system for labels and products. This top side labelling machine is highly appropriate for labeling various containers with different sizes, made from aluminum, glass, plastic, and batteries, cartons, pouches, etc. It also has an exclusive single point synchronized speed control system. Moreover, the built-in and preset label length detecting system helps to do away with the manual input and storage of label length details in the machine’s memory and also retrieving the same information every time in order to change the label size and restarting the equipment.

This automatic top side labeling system thus assists in saving time and money, prevents machine down time, and helps to increase the production. It is capable of providing an output of maximum 60 labels per minute, depending on product and label size. The top side labelling machine has easy to reach hand wheel adjustments, and also a side rail for quick adjustments. Hence it increases the up-time of the equipment. This elegant model incorporates the most recent and fastest Netcom control technology, to instantly activate the bright digital display screen for quick set-up. It is also suitable for a variety of flat package applications; and is highly effective and very durable. The equipment even includes a single point online speed variation control and an integrated A. C. variable frequency drive system. Besides it has a no change parts system for various sizes of labels; and a well synchronized speed for dispensing the labels, conveyor and pressing device. This virtually maintenance free machine has simple label placing adjustments and is even self protected against voltage fluctuations.