In the past, the labels were applied manually on the bottles, but then it was realised the job is not being done with speed and accuracy. Thus, to overcome these shortcomings, the labelling machines were invented. After that, lot many technological changes were brought in the labelling machines in order to meet the demands of competitive market. A bottle labelling machine can accurately place the label on the exact position of the bottle. As it is automatic, obviously it can complete the job of sticking labels quickly and accurately.

There are different types of labelling machines available with various features. Buying a labelling machine which suit to your specific production needs can never be a problem, if you study the technical specifications of the labelling machine in detail. The ongoing technological advancements and increasing demands of the industries have led the labelling machine manufacturers to come up with versatile labelling machines. Below mentioned are some of the labelling machines which are advanced in features and functionalities:-

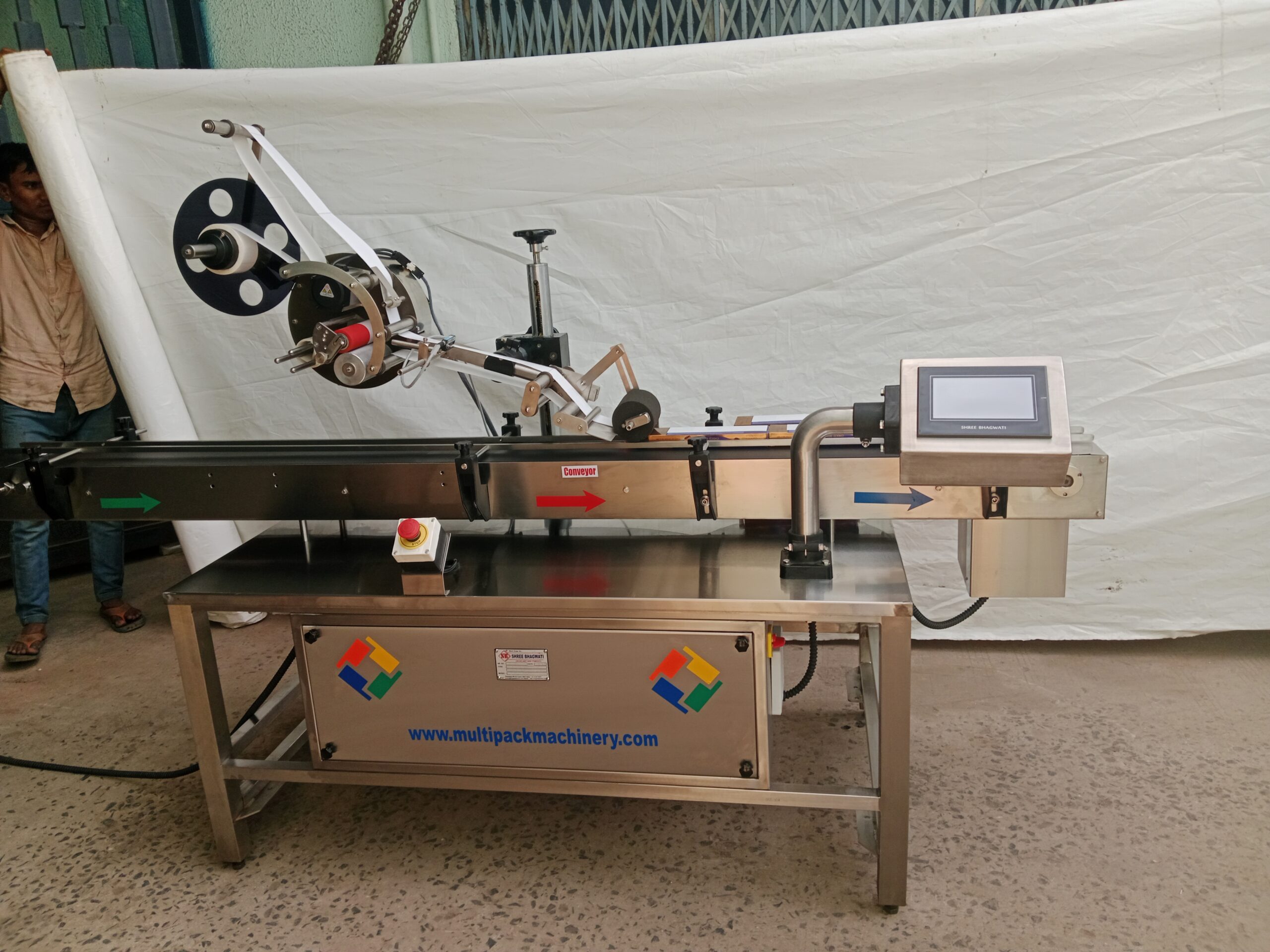

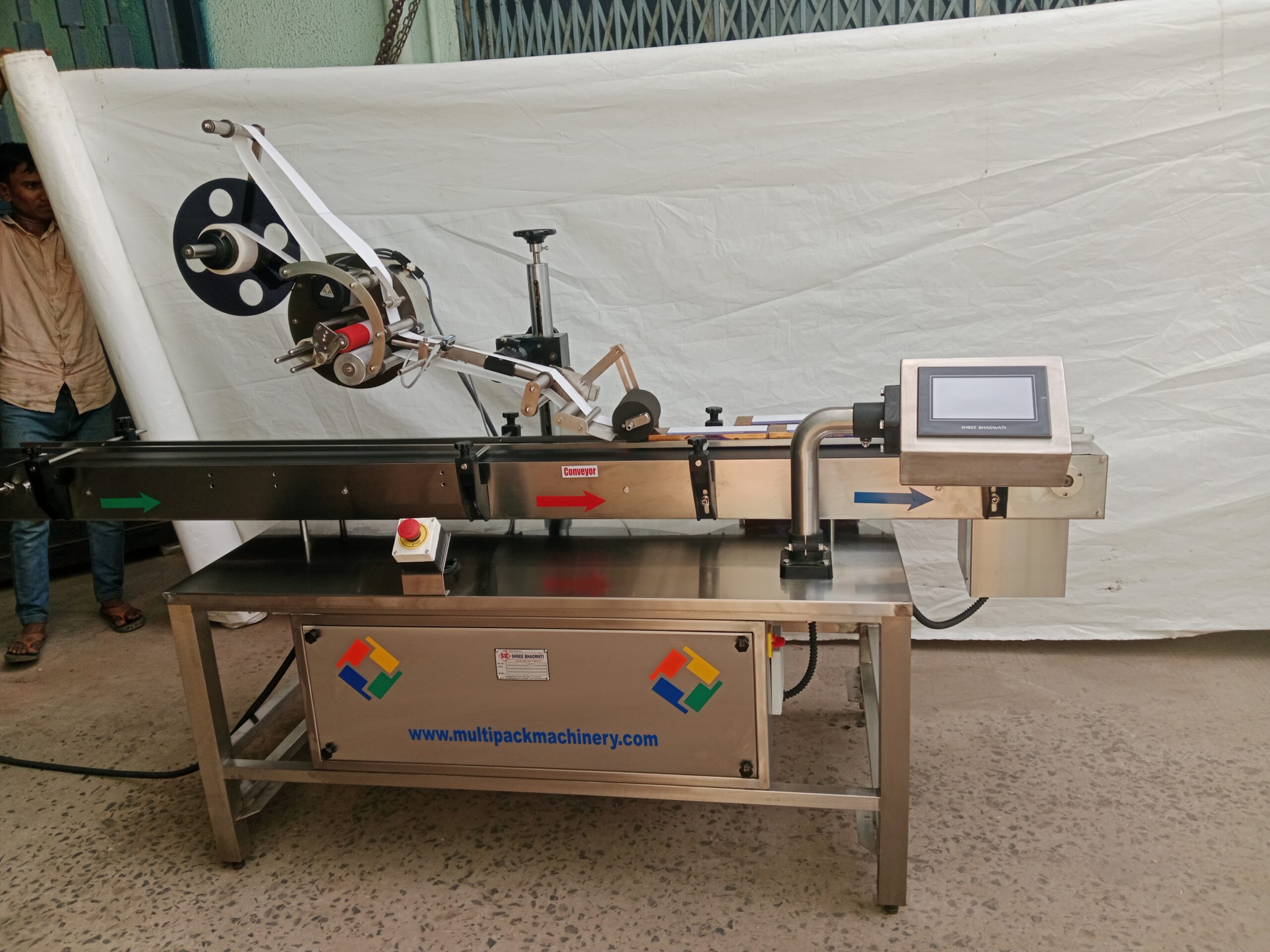

Single & Double Side Labeling Machine

The single side labelling machines are suitable for sticking labels on one side of the container, whereas a double side labelling machine can apply labels to both the sides of a container. The double side labelling machine saves time and can achieve high production as it can stick labels on the front, back, top and bottom side of the containers at the same time. The double side labelling machines are then further classified into front & back labelling machine as well as top & bottom labelling machine.

Front & Back Labeling Machine

The front & back labelling machines are just suitable in the situation where the labels need to be applied on the front and back side of the containers in different shapes like plane, round, oval, rectangular and round. The production speed of this machine obviously depends on the label size and the container size. Superior production levels can be achieved with the help of front & back labelling machine.

Top & Bottom Labeling Machine

You may have come across many products in the market having labels on the top and bottom. This has been possible with the help of top & bottom labelling machines with high end technology. The advanced features of this type of labelling machine include an inbuilt automated label length detection system. There is no need for manually feeding the length of the label and then changing the settings of the machine every time when the label size changes by restarting the machine. Thus, a top & bottom labelling machine saves lot of time and helps in achieving high rate of production.

Before selecting an appropriate labelling machine, all you need is to ask yourself is what will I need labelling machine for? The answer to this question would help you in deciding the best labelling machine suiting to your requirements.

This article has been written by Arjun Rao, Director of Shree Bhagwati Labelling Technologies