The FMCG industry in Ghana, Kenya and other African countries are booming. The region is home to a number of FMCG companies and Pharma companies are also setting up their plants. In addition to this, the market for medical devices and equipment including the healthcare sector. These sectors are highly competitive and need high-quality products. With the right labeling machine, you can make a huge business profit and branding with your labeling requirements.

An FMCG Labeling Machine is a crucial component for any production line in FMCG Industry. In addition to the basic structure, the machines also feature an automatic label feeder to keep track of label length and retrieve it as the product changes size. These features are extremely helpful in reducing downtime, increasing production, and reducing costs. A good FMCG Labeling Machine will meet all of these requirements. Here are a few of the advantages of an automatic sticker labeling machine.

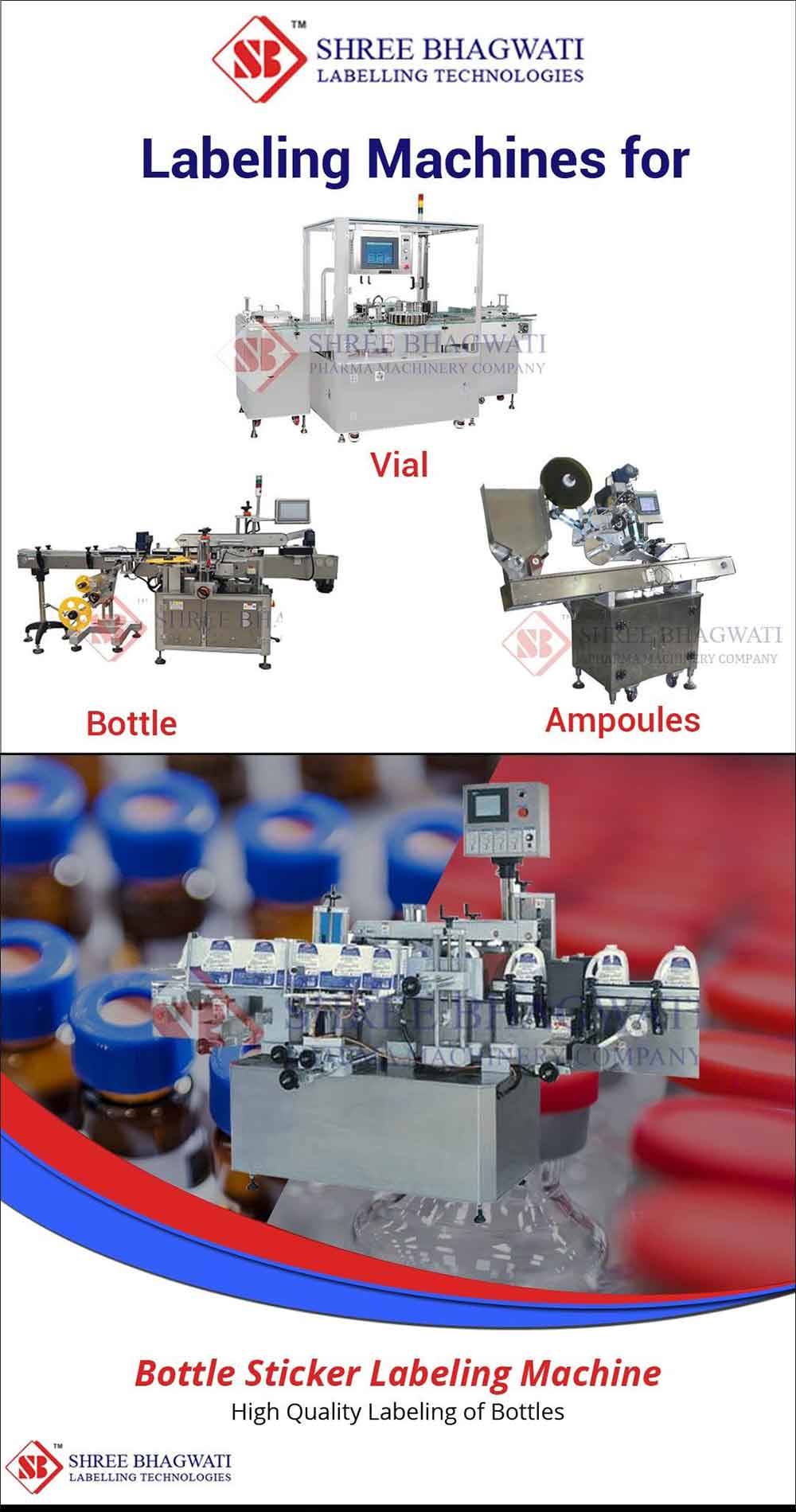

Self-adhesive labeling machines are used to apply labels to cylindrical objects, such as bottles and jars. This type of machine applies one or two labels to cylindrical containers. Stainless steel supports the machine’s design and construction. Stainless steel components are used to ensure longevity and durability. The labeling machine has a photoelectric gap sensor that detects the existing label and dispenses the next label accurately.

An FMCG Labeling Machine has the following advantages: An easy-to-use HMI makes setting the machine a breeze. You can easily adjust the speed of label dispensing, and you can even choose the number of labels to be dispensed. It also features a total counter and password-protected reset button. Moreover, the machine has a PPM-controlled AC drive and speed-control.

A sophisticated label applicator machine synchronizes all other functions. The machine’s software enables you to change the speed online. Besides, you can select the speed that best suits your needs. The control panel features an adjustable single-speed point, so that you can adjust speed as per your preferences. You can also use this machine to label glass bottles. The technology is highly advanced and easy to use.

A high-tech label applicator machine has a sophisticated control panel that can easily synchronize the functions of the machine. This allows for an automatic label applicator. It is able to apply various types of labels to a variety of container shapes. The Front back Wraparound Sticker Labelling Machine is suitable for both glass and plastic containers. The machines can apply different types of labels. If the container shape is cylindrical, the Front back Wraparound Sticker Applicator application machine is a versatile solution.

A fast-moving consumer goods labeling machine will be necessary for every type of packaging. It will make it easier for the consumer to read the labels and identify the products. An FMCG labeling machine is essential for food packaging. The machines will allow the labeling of various products. Further, the FMCG Labeling Machine will facilitate proper communication between suppliers and customers. Its small footprint allows it to work in the area of fast-moving consumer goods.