Product identification plays a crucial role in various industries, ensuring efficient and accurate labeling of goods. With advancements in technology, automatic labeling machines have emerged as valuable tools in the manufacturing and packaging processes. These machines offer numerous benefits, such as improved productivity, enhanced accuracy, and cost-effectiveness.

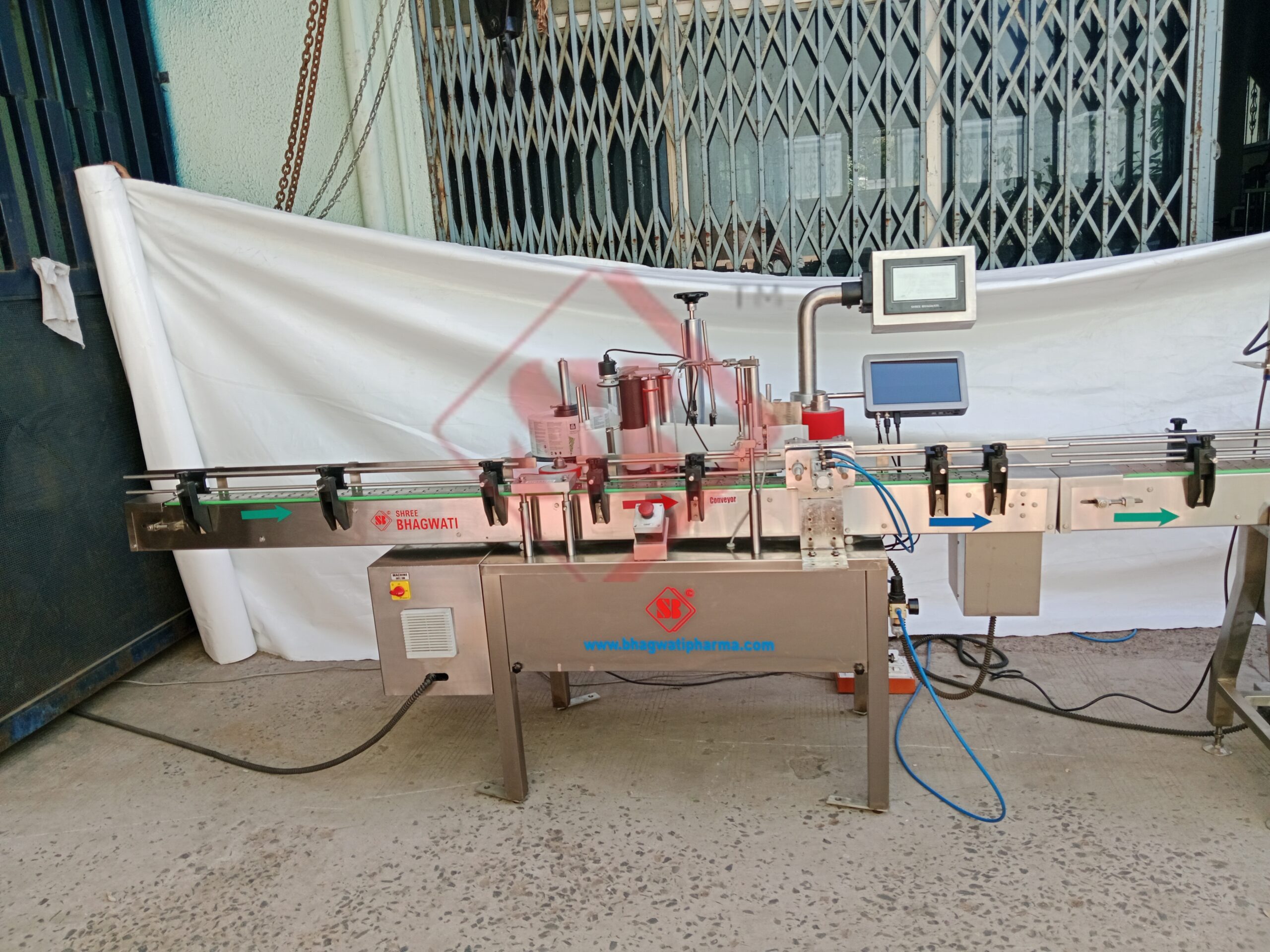

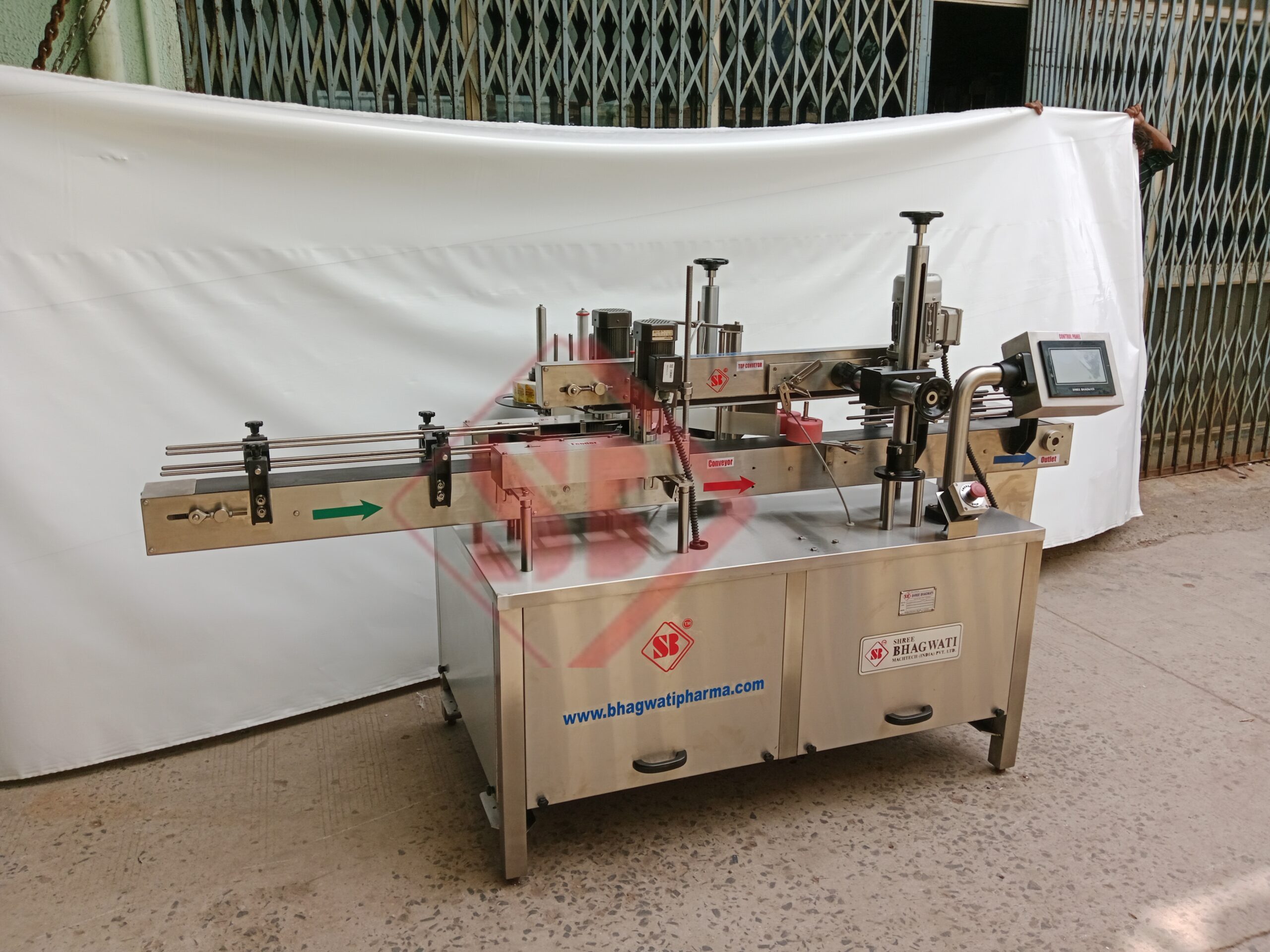

Automatic Labeling Machines can label a wide variety of products with great accuracy and consistency. This increases productivity and reduces labor costs. These machines can apply front and back labels or full wrap around labels on containers of different sizes. They are also ideal for applying decorative labels.

Choosing the right automatic labeling machine requires careful consideration of your production requirements and industry application. You must clearly define the label size and shape, speed, and accuracy needed.

Importance of Product Identification

In today’s competitive market, effective product identification is essential for businesses to establish their brand presence and ensure consumer satisfaction. Product labels convey vital information about the item, including its name, ingredients, usage instructions, and safety warnings. Accurate and clear labeling not only helps customers make informed purchasing decisions but also ensures compliance with regulatory standards.

Increased Efficiency and Productivity

Automatic labeling machines excel in speed and throughput, allowing businesses to label products swiftly and efficiently. They eliminate the need for manual labeling, reducing human error and accelerating the labeling process. With these machines, manufacturers can label thousands of products in a fraction of the time it would take using traditional methods.

Enhanced Accuracy and Consistency

Accurate label placement is crucial for product identification and brand integrity. Automatic labeling machines ensure precise positioning of labels on products, minimizing errors and inconsistencies. They maintain a high level of accuracy even when handling products with irregular shapes or uneven surfaces, guaranteeing uniform labeling across the entire product range.

Cost-effectiveness and Waste Reduction

By automating the labeling process, businesses can achieve cost savings in terms of labor, time, and materials. Automatic labeling machines eliminate the need for manual labor, reducing staffing requirements and associated costs. Moreover, these machines optimize label usage, minimizing waste and ensuring efficient utilization of labeling materials.

Versatility and Adaptability

Automatic labeling machines offer versatility in handling various product types, sizes, and shapes. They can accommodate different label formats and materials, allowing businesses to adapt their labeling requirements as needed. Whether it’s bottles, jars, boxes, or cans, these machines can efficiently label a wide range of products in different industries.

Applications of Automatic Labeling Machines

Food and Beverage Industry

In the food and beverage industry, automatic labeling machines play a vital role in labeling products with essential information, such as ingredients, nutritional facts, and expiry dates. These machines ensure compliance with labeling regulations and provide consumers with accurate information to make informed choices.

Pharmaceutical Industry

Pharmaceutical products require precise labeling to ensure patient safety and regulatory compliance. Automatic labeling machines are capable of accurately labeling pharmaceutical containers, such as vials, bottles, and blister packs, with critical information like dosage instructions, warnings, and batch numbers.

Cosmetics Industry

Cosmetic products often require attractive and visually appealing labels to catch the attention of consumers. Automatic labeling machines enable precise application of labels on cosmetic containers, enhancing product presentation and brand recognition. They ensure consistent labeling across a wide range of cosmetic items, including bottles, tubes, and jars.

Logistics and Distribution

Automatic labeling machines are extensively used in logistics and distribution centers to label packages and cartons. These machines streamline the labeling process, improving inventory management, and facilitating accurate tracking and tracing of products throughout the supply chain.

Future Trends in Automatic Labeling Technology

The automatic labeling machine industry is continuously evolving, driven by advancements in technology. Some future trends in this field include:

Integration with Artificial Intelligence (AI): Automatic labeling machines are expected to leverage AI capabilities for improved image recognition, label detection, and intelligent error correction. AI algorithms can help machines adapt to varying product shapes and sizes, further enhancing accuracy and efficiency. IoT Connectivity: The Internet of Things (IoT) has the potential to revolutionize automatic labeling machines. By connecting these machines to a network, manufacturers can gather real-time data, monitor performance, and remotely control operations. This connectivity enables proactive maintenance, reduces downtime, and facilitates seamless integration into smart manufacturing environments.

Sustainability and Eco-friendly Practices: As sustainability becomes a global priority, automatic labeling machines are likely to incorporate eco-friendly practices. This includes the use of recyclable labeling materials, energy-efficient components, and reduced waste generation. Such advancements align with the growing demand for environmentally conscious production processes.

Enhanced User Interfaces: Manufacturers are focusing on developing user-friendly interfaces for automatic labeling machines. Intuitive controls, touchscreens, and visual feedback systems simplify machine operation and minimize the learning curve for operators. These interfaces contribute to improved productivity and efficiency on the shop floor.

Multi-functional Labeling: Future automatic labeling machines may offer multi-functional capabilities, going beyond simple product identification. These machines could integrate additional functionalities such as printing batch numbers, applying security features, or affixing promotional labels. By combining multiple tasks into a single machine, manufacturers can further streamline their labeling processes.