The construction chemicals industry stands at the precipice of a monumental shift, propelled by technological advancements aimed at enhancing efficiency and precision. In this transformation, the role of Front and Back Double Side Labeling Machines emerges as a crucial element, revolutionizing the way labeling processes are optimized within this sector.

Revolutionizing Labeling in Construction Chemicals Industry

Understanding Front and Back Double Side Labeling Machines

What are Front and Back Double Side Labeling Machines?

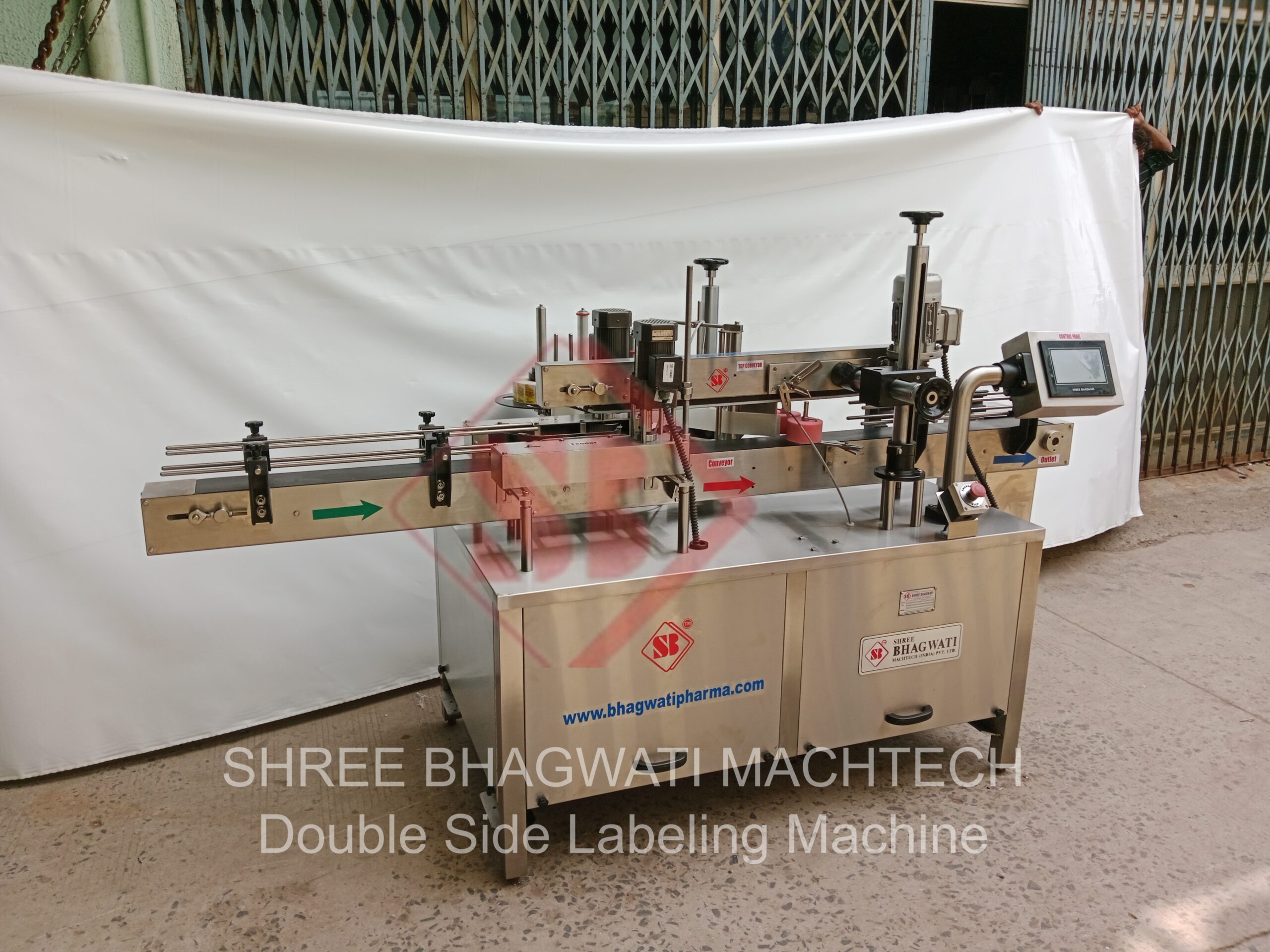

Front and Back Double Side Labeling Machines, commonly referred to as dual-side labelers, are sophisticated equipment designed to streamline the labeling process by affixing labels on both the front and back of containers simultaneously.

Types and Variations in These Machines

These labeling machines come in various configurations, ranging from semi-automatic to fully automatic, catering to diverse production scales and labeling requirements within the construction chemicals industry.

Importance of Labeling in Construction Chemicals

Role of Labeling in Product Identification

Accurate labeling plays a pivotal role in product identification, ensuring clarity and transparency in the chemical compositions and usage instructions of products within the construction sector.

Regulatory Compliance Through Accurate Labeling

Adhering to stringent regulatory standards is imperative in the chemical industry. Front and Back Double Side Labeling Machines assist in maintaining compliance by precisely displaying essential information and hazard warnings on chemical containers.

Efficiency Challenges Without Dedicated Labeling Machines

Manual labeling processes often result in inefficiencies, introducing inaccuracies and consuming valuable time that could otherwise be utilized for core production activities.

Inaccuracies and Time-consuming Processes

Human errors in manual labeling not only compromise accuracy but also prolong the labeling duration, hindering overall operational efficiency.

Benefits of Front and Back Double Side Labeling Machines

Optimizing Labeling Processes

These machines streamline the labeling process, significantly reducing the time required for labeling tasks while ensuring consistent accuracy and placement of labels.

Enhancing Efficiency and Accuracy

By automating the labeling process, these machines minimize errors, leading to improved efficiency and precision in labeling construction chemical containers.

How These Machines Work in Construction Chemicals Industry

Customization and Adaptability

Front and Back Double Side Labeling Machines offer customizable features, accommodating various container sizes and shapes, adapting seamlessly to the diverse labeling needs of the construction chemicals sector.

Streamlining the Labeling of Various Chemical Containers

From adhesive labels to shrink sleeves, these machines efficiently handle different labeling materials, catering to the requirements of various chemical containers.

Improvements Observed in Labeling Tasks

Increased accuracy, reduced labeling time, and minimized errors have been notable outcomes, leading to enhanced operational efficiency and customer satisfaction.

Advancements and Future Trends

Technological Innovations in Labeling Machines

Ongoing technological advancements continue to refine these labeling machines, incorporating features such as AI-driven label placement and remote monitoring for optimal performance.

Predictions for the Industry’s Future

The future of Front and Back Double Side Labeling Machines in the construction chemicals industry looks promising, with further enhancements expected to elevate efficiency and accuracy.

Conclusion: Transforming Labeling Efficiency in Construction Chemicals

In conclusion, Front and Back Double Side Labeling Machines represent a pivotal advancement in the construction chemicals sector. By optimizing labeling processes, these machines not only boost efficiency but also ensure accuracy and compliance, driving the industry towards a future marked by streamlined operations and enhanced product quality.

Unique FAQs

Are Front and Back Double Side Labeling Machines suitable for all container sizes and shapes?

These machines are highly adaptable and can be customized to accommodate various container sizes and shapes commonly used in the construction chemicals industry.

Do these machines require specialized training for operation?

While familiarity with the machine’s operation is necessary, most modern labeling machines come with user-friendly interfaces, minimizing the need for extensive training.

How do these labeling machines contribute to regulatory compliance?

Front and Back Double Side Labeling Machines ensure accurate and clear display of essential information, meeting regulatory standards and displaying hazard warnings effectively.

Can these machines handle different types of labeling materials?

Yes, these machines are designed to handle various labeling materials, from adhesive labels to shrink sleeves, providing versatility in the labeling process.

What are the primary benefits of using these machines in the construction chemicals industry?

The primary benefits include increased efficiency, minimized errors, reduced labeling time, and enhanced accuracy in labeling chemical containers.