In the world of honey packaging, the application of labels is a critical aspect that not only conveys essential information but also contributes to the overall branding and visual appeal of the product. The use of advanced labeling machines is essential to achieve precision and efficiency in applying different types of labels on various honey containers. This article explores the applications of front & back, top, tamper tab, wrap, and tapered wrap labels on different honey containers using specialized labeling machines.

Introduction

Honey containers come in various shapes and sizes, from traditional jars to squeezable bottles, each presenting unique challenges for labeling. The utilization of advanced labeling machines tailored for specific label applications ensures that honey products not only meet regulatory standards but also stand out on the shelf.

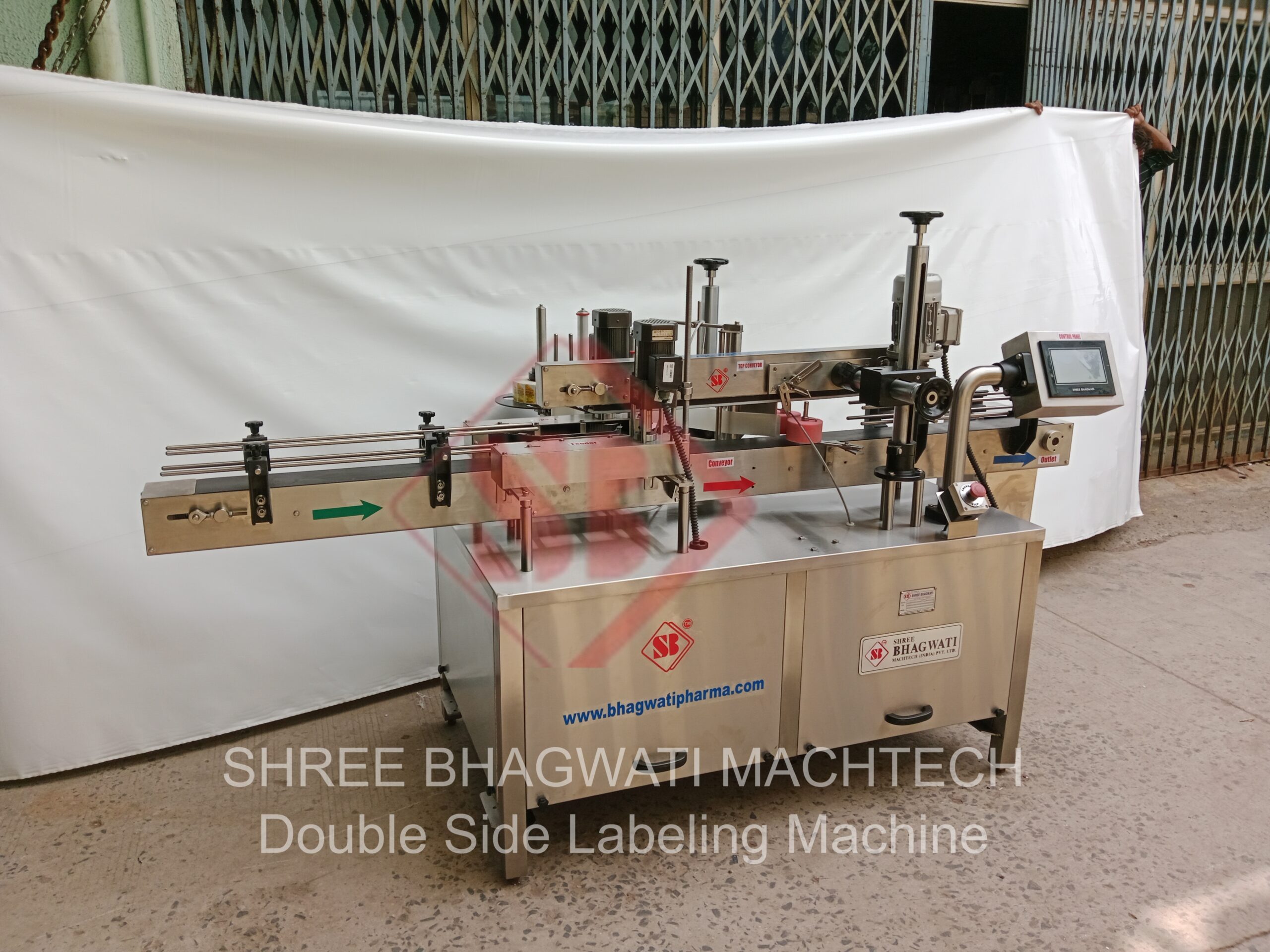

Front & Back Label Application

Front & back labeling is a common requirement for honey jars that allows for comprehensive information display. Specialized labeling machines are equipped with dual labeling heads, enabling simultaneous application of front and back labels with precision. This ensures that product details, nutritional information, and branding elements are prominently featured on the honey jar.

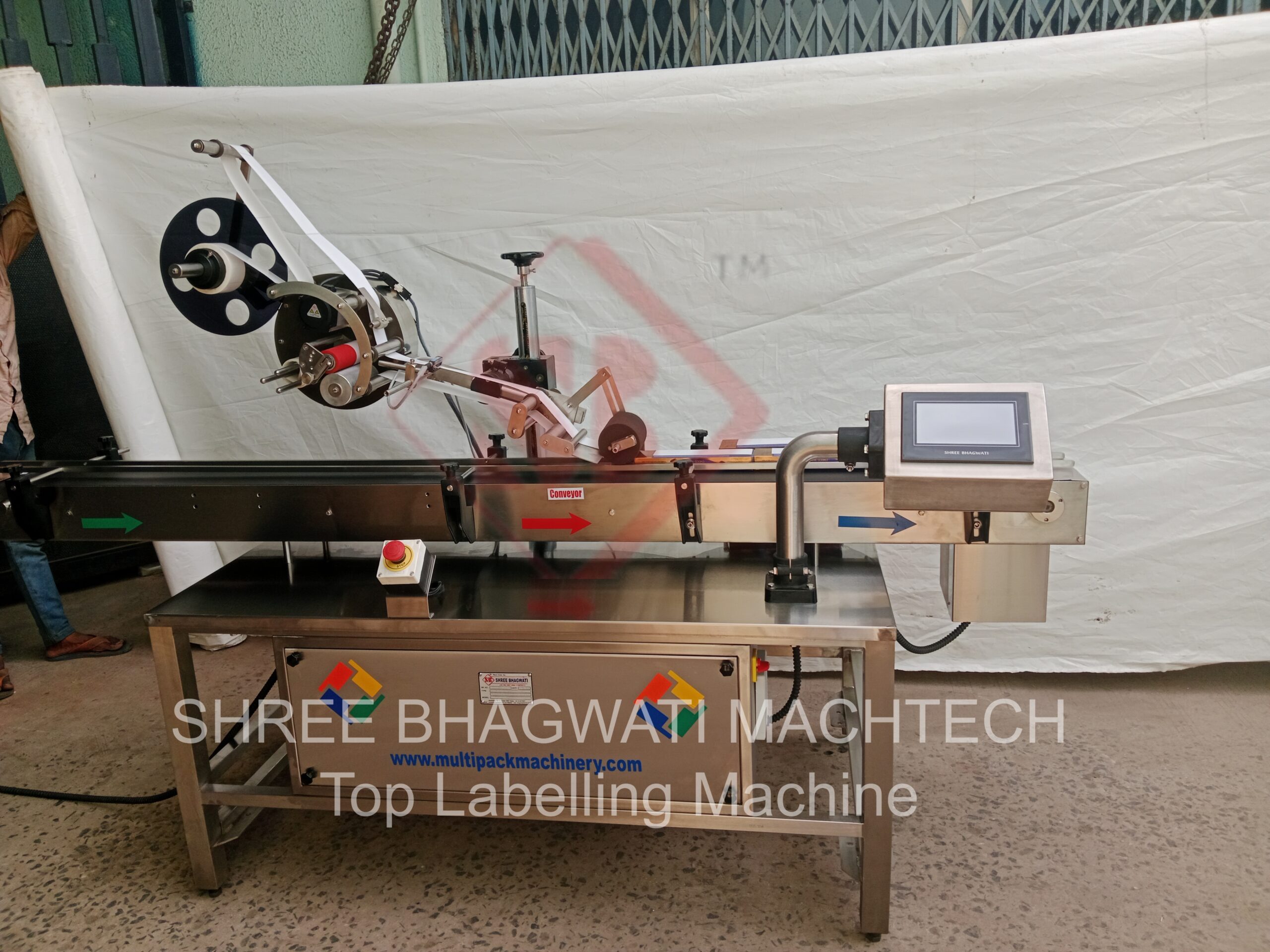

Top Label Application

Top labeling is essential for honey containers with a flat or concave lid. It provides an additional space to showcase the brand logo, product name, or any promotional information. Labeling machines equipped with top application modules ensure accurate label placement, even on lids with varying textures.

Tamper Tab Label Application

Ensuring the safety and integrity of honey products is paramount. Tamper-evident labels with perforated tabs are applied to honey jar lids using specialized labeling machines. These machines are designed to precisely position and seal tamper tabs, providing consumers with confidence in the product’s security and freshness.

Wrap Label Application

Wrap labeling is particularly relevant for honey containers with cylindrical or tapered shapes. The labeling machine applies a single continuous label around the circumference of the container, offering ample space for branding and product information. Advanced wrap labeling machines guarantee smooth application without wrinkles or misalignment.

Tapered Wrap Label Application

Tapered honey containers, such as those with a narrowing or conical shape, present a unique challenge for label application. Tapered wrap labeling machines are designed to handle these containers, ensuring that labels conform seamlessly to the shape without distortions. This precision is crucial for maintaining a professional and aesthetically pleasing appearance.

Choosing the Right Labeling Machine

Selecting the appropriate labeling machine for honey containers involves considering factors such as container shape, label type, and production speed. Manufacturers must choose machines with modular configurations, allowing for easy adaptation to different label applications. Additionally, features like label inspection systems contribute to quality control, ensuring that labels meet the highest standards.

Ensuring Regulatory Compliance

Honey packaging must adhere to regulatory standards, including accurate representation of nutritional facts, ingredients, and compliance with tamper-evident requirements. Utilizing labeling machines equipped with vision systems and sensors guarantees compliance with regulations, reducing the risk of errors and ensuring consumer safety.

Efficiency and Speed in Labeling

In a competitive market, the efficiency of the labeling process is crucial. High-speed labeling machines equipped with servo-driven technology ensure rapid and accurate label application, contributing to increased production output and overall operational efficiency.

Conclusion

In conclusion, the application of front & back, top, tamper tab, wrap, and tapered wrap labels on various honey containers demands specialized labeling machines. These machines, tailored for different label applications, not only ensure precision and efficiency but also contribute to the visual appeal and marketability of honey products. Choosing the right labeling machine is pivotal for meeting regulatory standards, maintaining efficiency, and creating an attractive product presentation in the highly competitive honey industry.