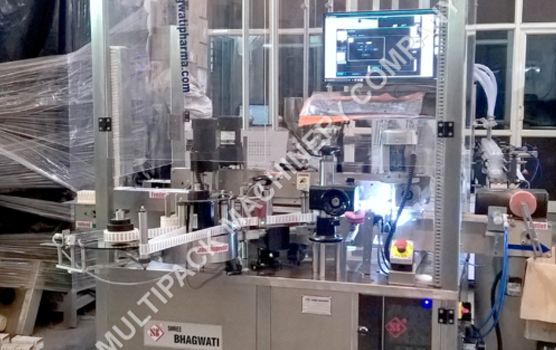

Security Seal Labeling Machine Front & Back Labeller Machine

Not only Single, We Take Care of Both Side of Your Labeling Needs

- Uses the reliable PLC Controlled Systems Labelling Head and controller – ensuring Ease of set up

- Full Synchronised speeds – incorporating Imported Stepper Motors / Servo Motor on the labelling heads and AC Brushless motors on all other drives

- Centralising & Aligning Squaring Chains / Screw Worms / Stabilizing Belts- for perfect product alignment without the need for change parts

- Independently Sprung Segmented Overhead Conveyor – allowing for bottle height variations

- Robust, heavy duty construction – the machine is designed for years of trouble free and maintenance free productivity. No lubrication or awkward adjustments are required

- Simple to Operate with the build it alarms and SR controller

- Economical design incorporating high reliability and low maintenance

| Labelling accuracy | ±1mm |

| PLC | Programmable Logic Controller Unit – DELTA Make |

| Touch Screen | Delta Make Touch screen |

| Stepper Motor | Sanyo denki stepper motor – Japan make |

| Servo Motor | Panasonic / Delta Make |

| Microprocessor | Microprocessor controller by Bhagwati make |

| Sensors ( Product / Label ) | Leuze – USA or Sick Germany make |

| AC Drive ( Variable Speed) | Delta Make |

| All Electrical / Electronic cables | Labb – Germany make |

| Pneumatic cylinders | SMC / Festo make |

| Label Height | 8 mm to 50 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia. | 400 mm |

| Film Roll Width with Core | 235mm* Maximum |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | Appx. 3 mm |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 2.5 Amp. |

| Capacity | 0.75 Kw |

| Speed | Up to 300 Labels per minute depending on Product Roll and Label |

MACHINE’S MATERIAL OF CONSTRUCTION

| Machine Main Base Frame | Mild Steel or Stainless Steel 304 |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Conveyor Belt | Rubber Belt (Stainless Steel – for heavy products) |

| Conveyor Shafts | Mild Steel with Hard Chrome or Zinc Plating |

| Conveyor Sprockets | Mild Steel or Nylon |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | ENP / Zinc / Hard Chrome / Blackening |

| TOP Conveyor Belt | Timing Sponge Belt |

| Guide Rod & Pin | Stainless Steel 304 |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |