Depending on the requirements, a Rotary Labelling Machine can be used for a number of purposes, including the application of adhesive labels to bottles, square containers and cylindrical containers. These machines are equipped with stepping motors, thermal heads and up to 4 rolling heads. They are made from stainless steel and incorporate advanced technology to ensure a high level of output. This article will explain the various types of rotary labelling machines available in the market.

Self-adhesive Labels

In the world of packaging, self-adhesive labels are crucial to the appearance of your products. This is especially true when it comes to products containing food, pharmaceuticals and OEM components. Reliable self-adhesive labelling is therefore essential in a wide variety of applications, from fast-moving consumer goods to complete production lines. HERMA is the number one destination for labels and self-adhesive materials backed by unique chain of know-how.

Prior art labelling equipment has its own limitations. Firstly, it requires separate labeling stations for each size and grade. The Rietheimer patent shows a dual cassette design, but it has three main weaknesses: knife edge label stripping, a complex fixed cam surface housing, and a lack of self-adhesiveness. Another flaw is the fact that it is limited to stiff labels.

Direct Application

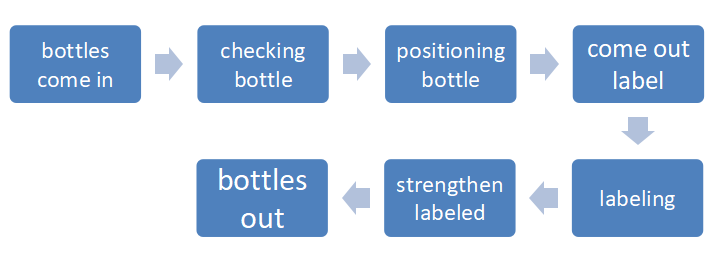

A rotary labelling machine is a type of automatic application system for packaging products. It applies labels to a product in a linear manner by transporting it around a continuously rotating base. The machine is typically equipped with multiple labelling heads. The number of platforms on the machine’s base determines the number of labelling heads it can accommodate. A small rotary labeller has only three labelling heads, while a larger machine has 24 platforms and up to five label applicators.

High Speed

The OBMA series of high-speed rotary labelling machines features an automatic, almost maintenance-free design. The machine does not need feed worms, star wheels or any other components that can cause problems. The rotary motion of the machine helps it to automatically apply labels to a wide range of products. With these machines, you do not have to worry about the label’s size. There is no need to input data on the label’s size, which makes it extremely convenient.

The machine’s self-adhesive heads are another feature. The labels are synchronised to the machine speed through a servo motor. These machines feature a menu guide for easy label positioning. They also come with programmable logic controls and ergonomic controls. The control panel is easy to use and allows you to select custom settings. A double roll holder is also available, which has a large loop buffer.

Safety

If you are using a Rotary labelling machine, you can be sure that you’re labeling your containers safely and correctly. This labeling machine features cooperating mechanisms that allow it to label containers of various sizes and types at unusually high speeds. The safety shields are quick to adjust and complete. You can use this machine in a variety of settings, including automatic, manual, and batch-size. Here are some safety tips:

rotary labelling machines have redundant or single label heads and can accommodate a wide variety of product sizes and shapes. it includes a safety-zero-access guarding package, which helps prevent label rejection during label application. Another safety feature is the option to automatically position the syringe before label application. These labelling machines are perfect for labelling injector devices in a vertical orientation, even at high speeds.

Cost

The rotary labelling machine is a highly versatile piece of equipment. It transports containers and bottles to a turntable, where individual platforms rotate to present the correct side of the product to the labeler. As the products pass through, they are labeled and usually wiped down for optimal wear. The rotary labelling machine’s price can vary, depending on the features you are looking for. Read on to learn about the types and features of this machine.

The rotary system is ideal for decorating wine, champagne, and distilled spirits. It is also equipped with multiple positioning methods, including pin and side lug placement. Nowadays, as brands struggle to differentiate their products from competitors, the rotary labelling system helps them do so efficiently. Because it is capable of labelling bottles of various sizes, it requires minimal changes to the machine’s parts. In addition, its high-speed operation makes it an ideal choice for companies that frequently change bottle shapes and sizes.

Technical Details

| Producing speed | 5,000~18,000BPH, can be adjusted freely |

| Conveyor speed | 0~30min, can be adjusted freely |

| Labeling accuracy | ±1mm |

| Label max width | 200mm |

| Label max length | 280mm |

| Machine weight | 2,500KG |

| Bottle max thickness | 130mm |

| Bottle min height | 120mm |

| Bottle max height | 400mm |

| Label inner diameter | φ76mm |

| Label outer diameter | φ400mm |

| (LxWxH) Machine size | 3300×1400×2140 (mm) |

| Power | 380V 50/60Hz 12,000W |

| Working temperature | 120~160℃ |

| Air supply | 8 (kg/cm2) |